Plastics are incredibly versatile materials that are utilized in a vast array of products and applications. Polytetrafluoroethylene (PTFE/Teflon) and polyetheretherketone (PEEK) are two of the most commonly used high-performance thermoplastic materials in industrial manufacturing applications. Both plastics offer unique properties that make them well-suited for various engineering applications. While both offer exceptional properties, there are key differences between PEEK and PTFE plastic that make each suitable for specific purposes. In this post, we will provide an overview of PEEK and PTFE materials, highlight their key advantages and disadvantages, and conduct an in-depth comparison of their specifications, properties, applications, cost, and other important considerations.

1. What is PEEK Plastic Material?

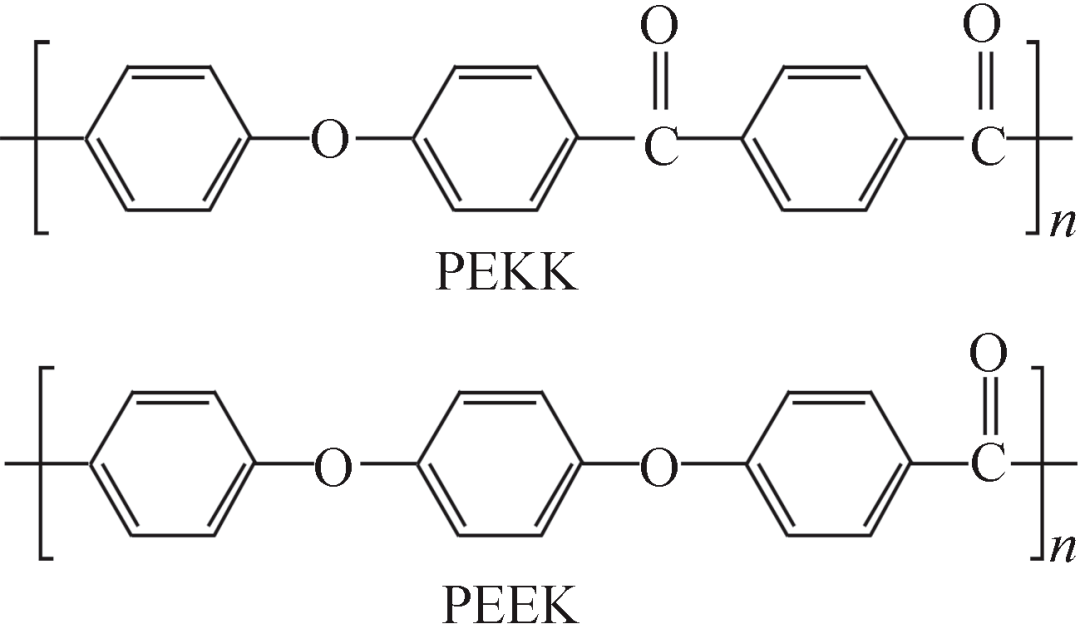

PEEK, full form polyetheretherketone, is a semi-crystalline thermoplastic that was first developed by Victrex in the late 1970s as an alternative to metal alloys in high-performance applications. As an engineering plastic, PEEK has exceptional rigidity and toughness even at high temperatures. It is known for its excellent chemical, corrosion, and wear resistance.

PEEK Chemical Structure & Composition

PEEK’s molecular structure features repeating units of aromatic rings interlinked by ether and ketone groups. This linear, semi-crystalline arrangement, with benzene rings, ether, and carbonyl groups, imparts the polymer with outstanding stability, strength, and resistance to various forms of degradation.

PEEK Chemical Formula

The backbone of PEEK consists of repeating units of oxygen-paraphenylene-oxy-carbonyl-paraphenylene. PEEK’s general chemical formula is (C19H12O3)n.

PEEK Temperature Range

PEEK can withstand continuous service temperatures up to 260°C (500°F) and is stable even in pressurized steam environments up to 300°C. Its glass transition temperature is 143°C, and its melting point is 334°C, enabling use in applications exposed to both high and low temperatures.

PEEK Plastic Properties

PEEK exhibits a remarkable balance of mechanical, thermal, chemical, and electrical properties. It features high strength and stiffness, outstanding wear and abrasion resistance, superior chemical compatibility with most solvents and acids, and excellent processability via injection molding, extrusion, and compression molding. PEEK offers stable performance across wide temperature ranges, low moisture absorption, high dielectric strength, good UV resistance (though not as high as PTFE), and is inherently flame retardant and biocompatible. Its insulation properties are excellent, making it suitable for electrical and electronic uses. PEEK is widely recognized for its durability, making it a preferred choice for applications in aerospace, automotive, medical, and semiconductor industries.

- High Strength & Rigidity: Tensile strength ranges from 94–186 MPa, with excellent modulus.

- Chemical Resistance: Inert to almost all organic and inorganic chemicals except highly concentrated nitric and sulfuric acids.

- Low Moisture Absorption: Water absorption is less than 0.5%.

- Superior Wear & Abrasion Resistance: Ideal for moving parts and bearings.

- Excellent Electrical Insulation: Maintains high dielectric strength and low loss at high frequencies.

- Biocompatibility: Non-toxic, suitable for medical implants.

- Flame Retardancy: Achieves UL94 V-0 rating.

- Radiation Resistance: Maintains properties under gamma and beta radiation.

- Self-lubricating: Suitable for applications requiring low friction.

PEEK Material Properties Chart

| Property | Value / Range |

|---|---|

| Density (g/cm³) | 1.33 |

| Melting Point (°C) | 343 – 387 |

| Thermal Expansion (cm/(cm·°C)) | 4.5 × 10⁻⁵ – 5.5 × 10⁻⁵ |

| Thermal Conductivity (W/m·K) | 0.29 |

| Heat Deflection Temp. (°C) | 152 – 172 (1.8 MPa) |

| Rockwell Hardness (M Scale) | M100 – M124 |

| Yield Strength (MPa) | 120 |

| Tensile Strength (MPa) | 3725 |

| Elongation at Break (%) | 15 – 45 |

| Flexural Modulus (MPa) | 4065 – 4275 |

| Impact Strength (kJ/m²) | No break |

| Dielectric Strength (V/mm) | 2.5 × 10⁴ – 3.3 × 10⁴ |

| Volume Resistivity (Ohm·cm) | 10¹⁶ |

| Dielectric Constant (1MHz) | 2.8 – 3.3 |

| Dissipation Factor (1MHz) | 0.001 – 0.005 |

| Water Absorption (%) | ≤ 0.1 |

| Flammability | UL94 V-0 |

| Chemical Compatibility | Excellent |

| Compression Molding | Yes |

| Heat Resistance | Excellent |

| Insulation | Excellent |

| UV Resistance | Moderate |

PEEK Plastic Applications

PEEK’s versatility is reflected in its broad range of uses:

Aerospace: Used in aircraft engine components, wing structures, satellite parts, and radomes due to its weather and heat resistance. Carbon or glass fiber-reinforced PEEK improves the strength and durability of critical aerospace parts.

Medical Devices: PEEK is widely used for MRI imaging devices, shielding, spinal fusion devices, reinforcement rods, artificial joints, and dental restorations. Its biocompatibility and similarity to human bone make it ideal for implants.

Automotive: Serves in engine inner covers, bearings, gaskets, seals, and clutch rings, often replacing metal parts to reduce weight and improve efficiency.

Electronics & Electrical: Used in wire coating, terminal blocks, motor insulation, and semiconductor wafer holders, thanks to its dimensional stability, purity, and superior electrical properties.

Energy & Semiconductors: PEEK is found in nuclear industry components, oil and gas extraction equipment, CMP retaining rings, and other high-performance parts that must withstand high temperatures and corrosive environments.

PEEK Plastic Cost

PEEK is more expensive than many other engineering plastics. The cost is justified by its advanced properties and the performance it brings in demanding applications. While it used to cost hundreds of thousands to millions of dollars for ownership and production, advances in processing and the expiration of key patents have made 3D printing and manufacturing with PEEK more affordable. Still, for most projects, PEEK remains a premium material.

PEEK Plastic Advantages & Disadvantages

Pros:

- Exceptional chemical and thermal stability

- High mechanical strength even at elevated temperatures

- Minimal moisture absorption

- Excellent wear and abrasion resistance

- Biocompatibility for medical use

- Can be processed by injection molding, extrusion, and 3D printing

Cons:

- Higher cost than most plastics

- Limited resistance to UV light

- Hydrophobic and non-polar, resulting in low cell adhesion for some medical uses

- Lower glass transition temperature compared to some other high-temperature polymers

2. What is PTFE Plastic Material (Teflon)?

PTFE, full name polytetrafluoroethylene (commonly known by the DuPont brand name Teflon), is a fluoropolymer thermoplastic resin. It was first discovered in 1938 and brought to market in the late 1940s. PTFE has a fully fluorinated carbon chain backbone, which gives it unique properties like exceptional chemical and heat resistance.

PTFE Chemical Structure & Composition

PTFE is a homopolymer of tetrafluoroethylene, with a completely symmetrical, unbranched linear polymer structure. The molecular structure of PTFE is made up of a carbon backbone shielded by fluorine atoms, which form strong C-F bonds. This arrangement protects the main carbon bonds from attack by other reactive molecules and gives PTFE its distinctive properties. The density of PTFE is approximately 2.280-2.295 g/cm³, and its crystallinity ranges from 93% to 98%. The helical, twisted chain structure results in a smooth, waxy surface that is non-polar and electrically neutral.

PTFE Chemical Formula

The chemical formula of PTFE is (C₂F₄)ₙ. Each repeating unit consists of two carbon atoms bonded to four fluorine atoms, forming a highly stable chain.

PTFE Temperature Range

PTFE is well-known for its outstanding temperature resistance. It can be used in environments as cold as -200°C and as hot as 260°C, and it can withstand even higher temperatures for short periods. This wide thermal range makes it highly suitable for demanding industrial and scientific applications. Wires insulated with PTFE, for example, can be used at temperatures between -60°C and +260°C.

PTFE Plastic Properties

PTFE is renowned for its outstanding chemical inertness, extremely low coefficient of friction, excellent weatherability, and broad temperature stability. It is chemically compatible with almost all substances, making it ideal for harsh environments. PTFE is highly flexible but has lower mechanical strength and wear resistance compared to PEEK. It offers excellent insulation, non-flammability, and resistance to UV and aging. PTFE can only be processed by special methods such as compression molding and machining due to its high melt viscosity. It is also highly resistant to creep and has nearly zero water absorption.

PTFE Plastic Properties

- Exceptional Chemical Resistance: Unaffected by almost all chemicals except for a few reactive metals at high temperatures.

- Low Friction: Known as the most slippery solid material.

- Non-stick Surface: Substances rarely adhere to its surface.

- Excellent Electrical Insulation: Maintains properties across a wide range of temperatures and frequencies.

- Non-flammability: Self-extinguishing and non-combustible.

- Low Water Absorption: Practically zero water absorption.

- Weather & Aging Resistance: Resistant to UV, ozone, and outdoor exposure.

- Flexible: Remains ductile even at very low temperatures.

PTFE (Teflon) Properties Chart

| Property | Value / Range |

|---|---|

| Density (g/cm³) | 2.16 – 2.20 |

| Melting Point (°C) | 327 |

| Thermal Expansion (×10⁻⁵/°C) | 10 – 20 |

| Thermal Conductivity (W/m·K) | 0.24 |

| Heat Deflection Temp. (°C) | Not specified (continuous use -200 to 260) |

| Hardness (Shore D) | ~50 – 60 |

| Yield Strength (MPa) | 7 – 28 |

| Tensile Strength (MPa) | 7 – 28 |

| Elongation at Break (%) | 100 – 400 |

| Compression Strength (MPa) | 24 (1% yield) |

| Impact Strength (kJ/m²) | No break |

| Dielectric Strength (V/mm) | 50 – 80 |

| Volume Resistivity (Ohm·cm) | ≥ 10¹⁸ |

| Dielectric Constant (1MHz) | 2.0 – 2.2 |

| Dissipation Factor (1MHz) | ≤ 2.5 × 10⁻⁴ |

| Water Absorption (%) | < 0.01 |

| Flammability | Non-flammable |

| Chemical Compatibility | Outstanding |

| Compression Molding | Yes |

| Heat Resistance | Excellent |

| Insulation | Outstanding |

| UV Resistance | Excellent |

PTFE Plastic Applications

PTFE’s properties have led to its use in a wide range of industries:

Cookware: Non-stick pans and bakeware rely on PTFE for their easy-release surfaces.

Electrical and Electronics: PTFE is used as an insulator in cables, printed circuit boards, and high-frequency electronics due to its low dielectric constant and stable performance.

Chemical Processing: Its chemical inertness makes it ideal for gaskets, seals, linings, and piping used with aggressive chemicals.

Medical Devices: PTFE is used in implants, tubes, and catheters because it is non-reactive and biocompatible.

Mechanical Components: Bearings, gears, and sliding parts benefit from PTFE’s low friction and wear resistance.

Industrial Coatings: PTFE is applied as a protective coating on various surfaces to provide durability and prevent sticking.

PTFE Plastic Cost

PTFE is more expensive than many common plastics. The cost is influenced by the complex manufacturing process and the specialized equipment required for processing. In addition, PTFE is not as easy to mass-produce as some other plastics, which also impacts price.

PTFE Plastic Advantages & Disadvantages

Pros:

- Outstanding chemical resistance

- Wide temperature range

- Exceptional electrical insulation

- Low friction and non-stick properties

- Excellent resistance to weathering and UV

- Does not support combustion

Cons:

- PTFE has relatively low mechanical strength and is not suitable for structural applications

- Poor wear and abrasion resistance compared to some engineering plastics

- Processing can be challenging and often requires special equipment

- PTFE cannot be welded or cemented

- Tends to be more costly than most standard plastics

- High coefficient of thermal expansion can lead to notable dimensional changes with temperature

3. PEEK vs PTFE (Teflon) Plastic: What are the Differences

As we have taken a deep breakdown of the two plastic materials, here we will only use a brief table to sort out the differences between PTFE and PEEK for your quick reading:

| Property | PEEK | PTFE |

|---|---|---|

| Chemical Formula | (C19H12O3)n | (C₂F₄)ₙ |

| Structure | Aromatic, semi-crystalline | Linear, fully fluorinated |

| Temperature Range | -60°C to 260°C (up to 300°C short) | -200°C to 260°C (up to 300°C short) |

| Mechanical Strength | Very high | Moderate to low |

| Wear Resistance | Excellent | Poor to moderate |

| Chemical Resistance | Excellent (except strong acids) | Outstanding (nearly universal) |

| Friction | Low (improved with fillers) | Extremely low (superior to PEEK) |

| Electrical Insulation | Excellent | Outstanding |

| Moisture Absorption | Very low | Practically zero |

| Processability | Injection molding, extrusion, 3D | Compression molding, machining |

| Biocompatibility | Yes (medical implants) | Yes (implants, catheters) |

| Cost | High | High |

| UV Resistance | Low | Excellent |

| Flame Resistance | Self-extinguishing (UL94 V-0) | Non-flammable, self-extinguishing |

4. PEEK vs PTFE Plastic: Which is Better For Your Project?

Selecting between PEEK and PTFE depends on your application’s requirements. PEEK is the go-to choice for parts needing high mechanical strength, excellent wear resistance, and the ability to perform under significant load and temperature. It is ideal for demanding industrial, automotive, aerospace, and medical uses, especially when a combination of chemical, thermal, and mechanical performance is needed.

PTFE, on the other hand, shines in scenarios where chemical inertness, non-stick surfaces, and electrical insulation are paramount, but mechanical strength is less critical. It’s the preferred material for seals, gaskets, linings, and electrical insulation where chemical exposure or low friction is a must.

- Choose PEEK for structural components, parts requiring high strength and durability, and applications exposed to both chemicals and mechanical stress.

- Choose PTFE for non-stick, chemically inert, and electrically insulating applications where mechanical loads are lower.

When considering cost, processing methods, and the specific environment your part will face, both PEEK and PTFE offer unique advantages that can lead to long-lasting, reliable solutions in high-performance applications.